Table of Contents

In today's dynamic industrial environment, process automation is a key factor ensuring production efficiency and competitiveness. Our range of 11 advanced KUKA industrial robots responds to the growing demand for effective and intelligent solutions in the industry. In this article, we will take a closer look at the specifications and practical applications of these innovative models, which represent the highest technological level in the field of industrial robotics.

Introduction

In today's dynamic industrial environment, process automation has become a key factor influencing production efficiency and competitiveness. Our new offering, comprising 11 advanced KUKA industrial robots, addresses the growing market demand for intelligent, efficient, and future-oriented solutions.

KUKA robots have long enjoyed global recognition in the field of industrial robotics, based on the company's over sixty years of experience. They set the standard for innovation and efficiency in industrial automation. Thanks to their load capacity, precision, and reliability, they are excellent tools for use in Industry 4.0, where modern industrial solutions are required.

In this article, we will discuss each of these models in detail, analyzing their specifications and practical applications in various industrial sectors.

KUKA Robots Presentation

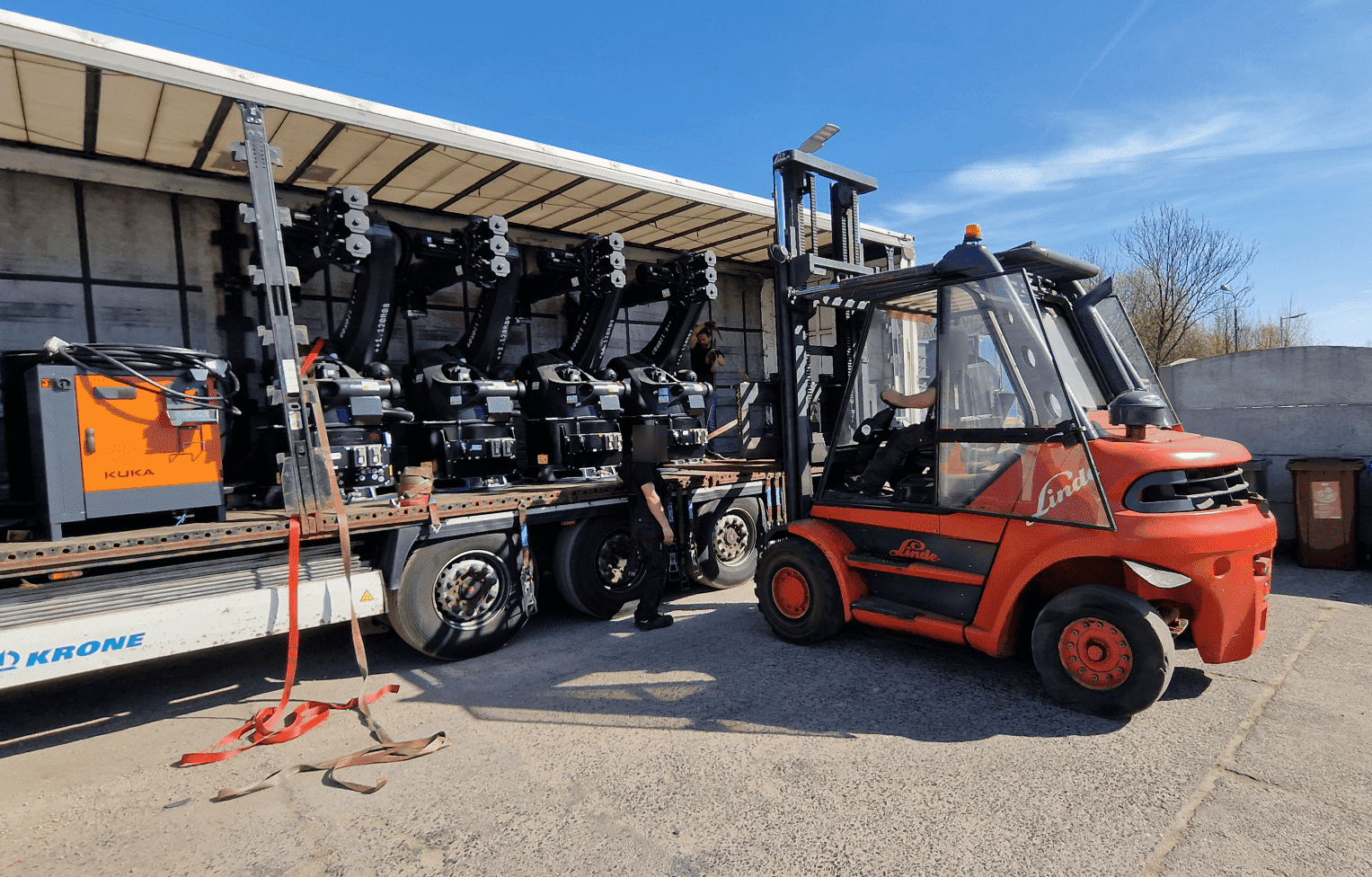

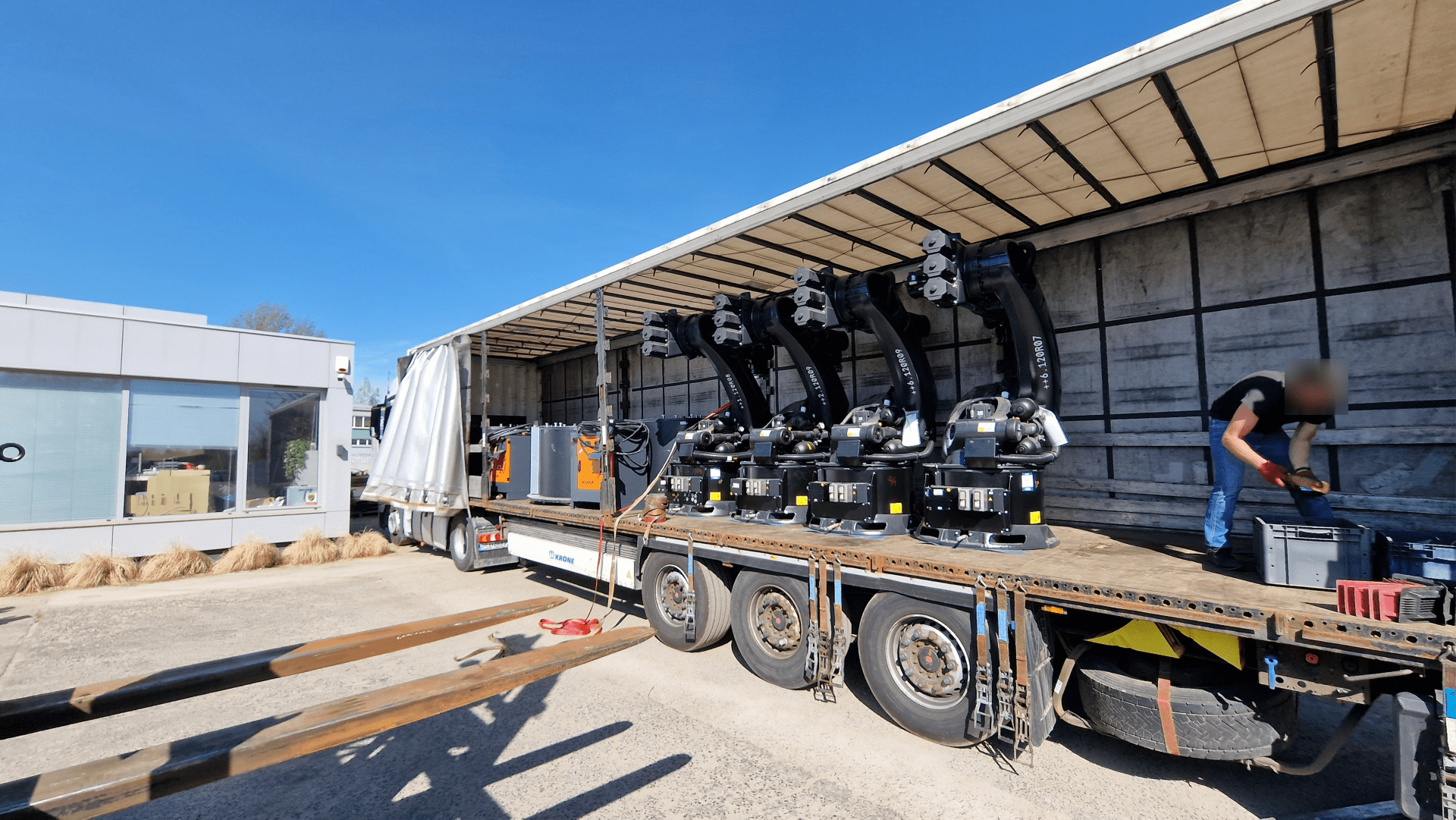

Our new offering consists of 11 advanced KUKA robots. Each of them is characterized by high technical parameters, ideal for automating industrial processes. There are three models available:

Additionally, we offer Expert EL390/1301 linear positioners - 8 units.

Below are detailed specifications for each of them:

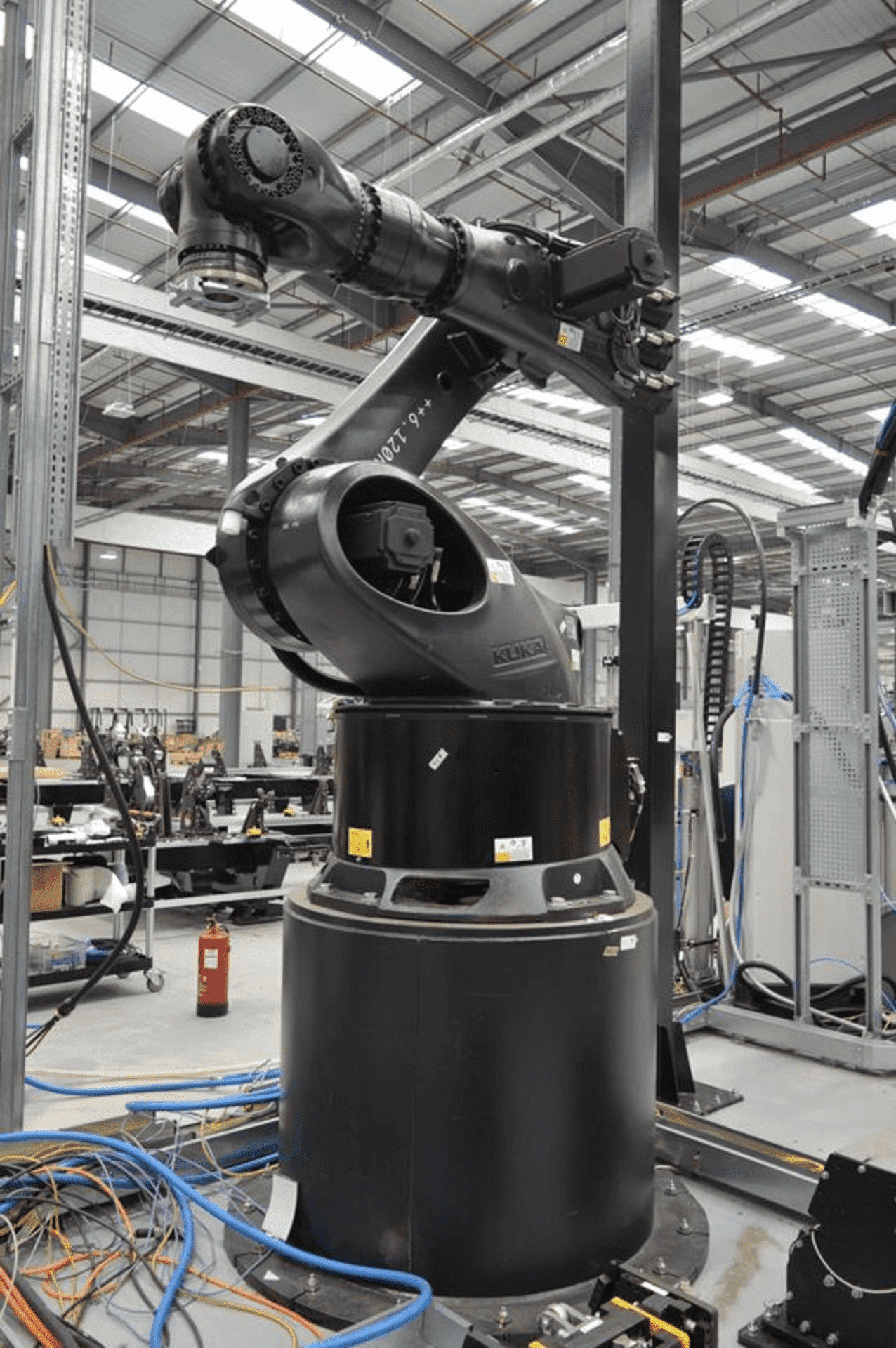

Serial number: 1077735

Quantity: 1 unit

Year of production: 2021

Condition: Used

Maximum reach: 2701 mm

Rated payload: 210 kg

Maximum payload: 275 kg

Number of axes: 6

Control system: KR C4

Additional information: Equipped with a remote control with serial number: 3095975

(Installed in an electric car production facility - never operated)

Serial number: 4380891

Quantity: 8 units

Year of production: 2021

Condition: Used

Maximum reach: 3076 mm

Rated payload: 280 kg

Maximum payload: 356 kg

Number of axes: 6

Control system: KR C4

Additional information: Equipped with a remote control with serial number: 3089845

(Installed in an electric car production facility - never operated)

Serial number: 4380799

Quantity: 2 units

Year of production: 2021

Condition: Used

Maximum reach: 2826 mm

Rated payload: 360 kg

Maximum payload: 472 kg

Number of axes: 6

Control system: KR C4

Additional information: Equipped with a remote control with serial number: 3087389

(Installed in an electric car production facility - never operated)

Advantages and Applications of KUKA Robots in Production

Our offering includes three advanced KUKA robots, representing the latest technology in industrial automation. Below are the key advantages and applications of these robots:

- KUKA Robotics Technology: KUKA robots, such as the KR210/R2700, KR280/R3080, and KR360/R2830/FLR models, are based on advanced technology, ensuring reliability, precision, and intelligent solutions for the industry.

- Production Applications: Our KUKA robots are an ideal solution for industries where automation of production lines is a key element in process optimization. With high payload capacity, large reach, and advanced control capabilities, KUKA robots excel as efficient tools for industrial production.

- Robotics Innovations: KUKA robots represent an innovative approach to automation, enabling rapid adaptation to changing market conditions and customer needs.

- Production Line Automation: With our KUKA robots, comprehensive automation of production lines is possible, resulting in increased efficiency and optimization of operational costs.

- Intelligent Solutions for Industry: By implementing KUKA robots, we introduce intelligent solutions to the industry that support innovation, improve working conditions, and enhance competitiveness in the market.

Expert EL390/1301 Linear Positioners

The Expert EL390/1301 linear positioners are another element of our offering that perfectly complements KUKA robots, providing precise and effective control over the X and Z axes in production processes. Below are the details regarding these linear positioners:

- Purpose: The Expert EL390/1301 linear positioners are specifically designed to collaborate with industrial robots, enabling precise positioning in the X and Z axes.

- Traversal: They feature a traversal length of 8000 mm, allowing for manipulation and movement along long production routes.

- Length: They offer a total length of 9000 mm, facilitating the handling of extensive production areas.

The Expert EL390/1301 linear positioners are a reliable tool for optimizing production processes, especially where precision and effective axis control are crucial. Their integration with KUKA robots provides a comprehensive solution for modern manufacturing plants, allowing for the optimization of production lines and increased efficiency.

With the precise Expert EL390/1301 linear positioners, we can offer customers not only advanced KUKA robots but also additional tools that comprehensively support automation processes and enhance competitiveness in today's industry.

Summary

The new offering of 11 advanced KUKA robots enriches our portfolio with tools for automating industrial processes. KUKA robots address the needs of the evolving industry, enabling increased production efficiency and performance improvement.

The application of KUKA robots in various industrial sectors allows for comprehensive automation of production lines and the introduction of innovative solutions to processes. Thanks to the intelligent features and precision of KUKA robots, it is possible to achieve operational cost optimization and production efficiency improvement.

Furthermore, the Expert EL390/1301 linear positioners work seamlessly with KUKA robots, enabling precise control over the X and Z axes in production processes. This comprehensive solution supports automation processes and enhances competitiveness in the market.

With modern automation technologies, our offering contributes to increasing production efficiency and refining production processes. We invite you to contact us for more information about our solutions and their potential application in your production facility.