Table of Contents

MIR GIBAS mobile robots are modern autonomous transport systems that improve logistics and production. Thanks to LiDAR technology, AI and full automation, they increase efficiency, reduce costs and eliminate downtime.

1. Introduction

Automation of logistics and production processes has become a key element of modern industry, and intelligent technologies are driving the development of Industry 4.0. In response to the growing needs of enterprises in terms of efficiency, safety and cost optimization, MIR GIBAS mobile robots offer an innovative approach to internal transport.

Thanks to autonomous navigation systems and artificial intelligence, MIR GIBAS robots can transport materials independently. They use advanced algorithms to avoid obstacles. This eliminates the need for human assistance and reduces downtime. Their versatility makes them applicable in a wide range of industries - from industrial production to logistics centers and the medical sector.

2. Innovative MIR GIBAS mobile robots

MIR GIBAS mobile robots, available in our offer, are modern autonomous transport systems that significantly improve logistics processes in production plants, warehouses and distribution centers. Thanks to advanced navigation technologies and artificial intelligence, they can move independently around the company's premises, transporting materials, components and finished products without the need for human intervention.

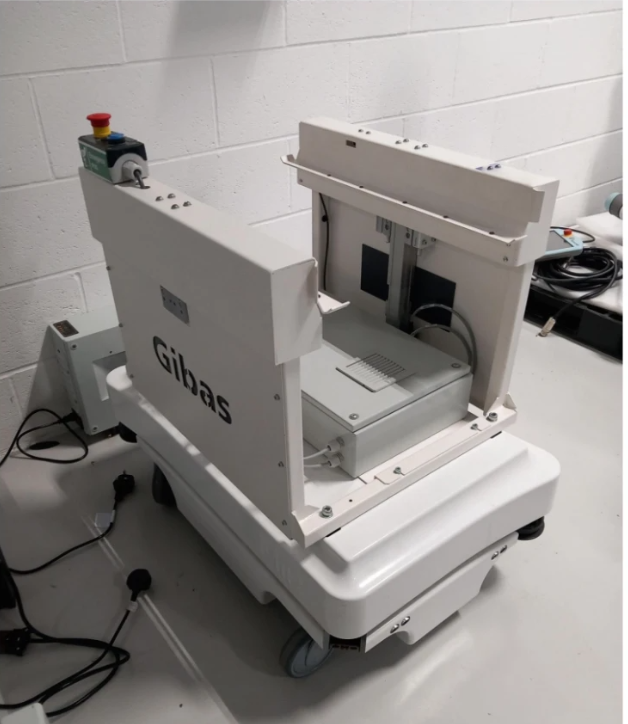

- Type: 4-wheel MIR with Gibas body and charger + new batteries from 2025 with warranty

- Condition: Brand new

- Quantity: 2 pieces

Key Features and Technologies

MIR GIBAS robots feature a number of advanced features that make them ideal for modern enterprises:

- Autonomous navigation – The robots use LiDAR technology, 3D cameras and SLAM systems. These technologies help them map their surroundings. Thanks to them, they can move safely, even in a changing environment.

- Safe cooperation with people – Sensor systems and artificial intelligence algorithms help MIR GIBAS robots. Thanks to them, the robots detect obstacles and change their route in real time. This makes them ideal for working in places where people move.

- Easy configuration and scalability – The robots can be quickly deployed in different parts of the plant. They can be integrated with existing infrastructure. This allows them to be gradually expanded as the company grows.

- Efficient fleet management – The ability to synchronize multiple robots within a single system allows for comprehensive optimization of internal transport, eliminating unnecessary downtime and increasing operational efficiency.

3. Benefits of using MIR GIBAS robots

Implementing MIR GIBAS mobile robots brings a number of benefits for companies that strive to optimize logistics and production processes. Thanks to modern technologies and intelligent management systems, these autonomous machines can significantly improve operational efficiency, increase safety and reduce costs.

Optimization of logistics processes

- Automatic material transport – MIR GIBAS robots can independently move raw materials, components and finished products between workstations, warehouses and production lines.

- Elimination of bottlenecks – Thanks to intelligent route management, robots optimize the flow of materials, which allows to avoid congestions and downtime in production.

- Integration with management systems (ERP, WMS, MES) – The ability to connect robots with IT systems allows for automatic transport planning and full control over logistics processes.

- Faster order fulfillment time – Autonomous robots can work without interruptions, which significantly shortens the time of internal deliveries and speeds up order fulfillment.

Reduction of operating costs

- Lower expenses for internal transport – Automation of the material transport process eliminates the need to engage employees in simple and time-consuming tasks.

- Reduction of costs related to human errors – Robots work precisely and consistently, which reduces the risk of errors in deliveries, damage to goods or losses resulting from inefficient logistics.

- Optimization of warehouse space – Thanks to the use of robots, it is possible to better use the available space, which reduces the need to expand the warehouse infrastructure.

- Lower operating costs – MIR GIBAS robots consume less energy than traditional transport systems (e.g. forklifts) and require minimal maintenance.

Improving occupational safety

- Eliminating hazards associated with manual transport – Robots reduce the risk of injuries resulting from moving heavy loads or collisions with forklifts.

- Advanced obstacle avoidance systems – Using LiDAR technology, sensors and artificial intelligence algorithms, robots safely navigate dynamic environments, avoiding people and objects.

- Working in difficult conditions – Robots can operate in high-risk areas (e.g. high-temperature zones, chemical warehouses), reducing employee exposure to hazardous conditions.

Scalability and flexibility of implementation

- Ease of integration with existing infrastructure – MIR GIBAS robots can be implemented gradually, without the need for costly plant modernization.

- Possibility of fleet expansion – As the company grows, the number of robots can be increased, creating intelligent internal logistics management systems.

4. Application in various industries

MIR GIBAS robots are widely used in various industrial sectors, including:

- Manufacturing industry – Automatic transport of components between workstations, supply of raw materials to production lines and collection of finished products.

- Warehouses and logistics – Optimization of storage processes, fast movement of pallets, packages and goods between storage areas.

- Medical sector – Automatic delivery of medicines, laboratory samples and medical equipment in hospitals and laboratories.

- Automotive – Support in the production processes of cars and spare parts through autonomous transport of elements within production plants.

MIR GIBAS robots are the future of automation of transport processes in modern companies. Thanks to their versatility, safety and ease of implementation, companies can achieve higher operational efficiency and significantly reduce labor costs.

5. Summary

MIR GIBAS mobile robots are a technologically advanced solution that supports companies in the automation of internal transport. Thanks to autonomous navigation, artificial intelligence and integration with ERP, WMS and MES systems, they significantly improve the flow of materials, eliminating bottlenecks and increasing the efficiency of logistics processes.

Their use brings real operational benefits - it reduces transport costs, reduces the risk of human errors and improves work safety. Additionally, robots can work in difficult conditions and dynamic environments, adapting to changes in the workspace.

Thanks to easy configuration and scalability, MIR GIBAS is a flexible solution. It can be implemented in small and large production plants, distribution centers and in the medical sector. This is a future-proof investment that allows companies not only to increase competitiveness, but also to meet the growing requirements in the field of automation and cost optimization.

MIR GIBAS is a step towards intelligent, efficient and safe logistics of the future!