Table of Contents

In this article, we take a closer look at KUKA robots, their features, applications, and importance in key sectors of the economy. Find out why these versatile and precise machines have become an indispensable tool in industry, logistics, and many other areas, revolutionizing the way modern companies operate.

1. Introduction to KUKA robots

KUKA, founded in 1898 in Germany, is a global leader in robotics and automation. In 1973, the company introduced the first industrial robot – FAMULUS, with innovative electric drives. Today, as part of the Midea Group, KUKA develops technologies that support Industry 4.0, such as integration with IoT and artificial intelligence. KUKA robots stand out from the competition thanks to their unique combination of modern technologies and practical solutions.

The main features are:

- Versatility: KUKA robots can be used in various industries, from heavy industry to medicine, thanks to a wide range of models and configurations.

- Precision: The high accuracy of the tasks performed makes KUKA robots indispensable in processes that require maximum precision, such as mechanical processing or surgery.

- Intelligent software: The company offers advanced control systems that allow easy integration of robots into existing production processes.

- Flexibility: KUKA robots can be adapted to the user's individual needs thanks to their modular design and extensive range of accessories.

- Durability: Thanks to high-quality materials and well-thought-out design, KUKA robots are characterized by a long service life and reliability in difficult working conditions.

2. Robotics in industry

KUKA robots have been the foundation of automation in industry for years, offering solutions that improve the efficiency, precision and safety of production processes. The most important applications of KUKA robots in various industrial sectors are discussed below.

2.1. Automated production lines

KUKA robots are widely used to automate production processes.

In the automotive industry in particular, KUKA robots play a key role, performing tasks such as:

- Welding car bodies: KUKA welding robots provide precise and fast joints, which speeds up vehicle production.

- Assembly of components: Thanks to their versatility, robots can assemble both large components and small parts that require precision.

- Painting and varnishing: Specialized robot models ensure uniform application of paints and protective coatings, reducing material waste and environmental pollution.

2.2. Mechanical and precision machining

In the mechanical industry, KUKA robots are indispensable for tasks that require high precision, such as:

- Milling: KUKA robots can be equipped with tools for material processing, making them the ideal solution for the production of mechanical components.

- Grinding and polishing: Robots are able to achieve excellent surface finishes, especially in the aerospace or medical industry, where standards are exceptionally high.

- Laser and water cutting: KUKA offers solutions for fast and precise cutting of various materials, from metals to plastics.

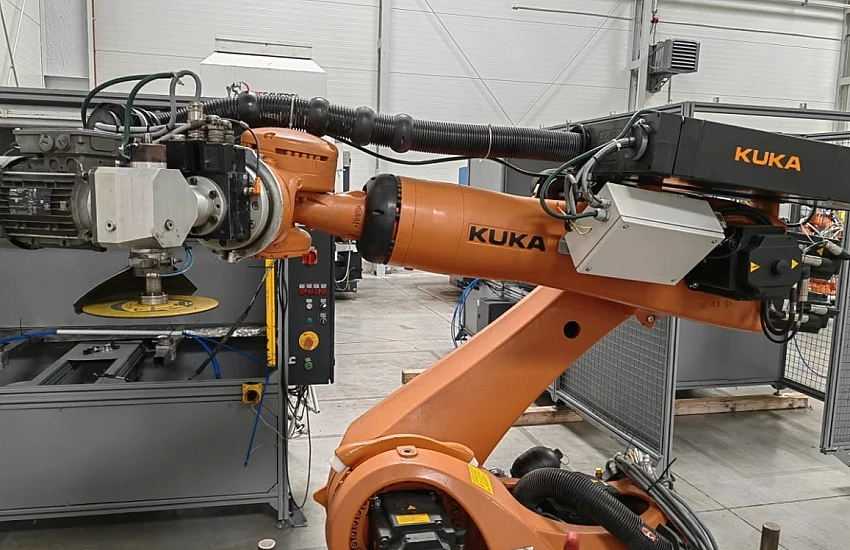

An example of an excellent tool in this field is the Kuka KR 210 R2700 prime with rotary table.

This 2015 grinding and cutting robot offers:

- A massive 2700 mm reach and 210 kg payload – ideal for handling large and heavy components in the automotive, aerospace and medical industries.

- 6 axes of motion – ensuring smooth and precise machining in the most difficult production environments.

- KRC4 control – an advanced system enabling intuitive operation, quick integration into existing production lines and maximum efficiency.

- 2D rotary table – increases flexibility, enabling complex machining without having to interrupt work.

3. Robots in logistics

KUKA robots are playing an increasingly important role in logistics, where precise, fast and reliable processes for material handling, storage and distribution are required. Thanks to advanced technologies and flexibility, KUKA offers solutions that help companies streamline the entire supply chain.

3.1. Storage and sorting

In modern warehouses, automation has become the standard, and KUKA robots are leading the way in tasks such as:

- Picking and stacking goods: Robots can precisely pick and place products on shelves, even in very tight storage spaces.

- Sorting parcels: Equipped with advanced vision systems, robots can quickly identify and sort parcels according to specific criteria such as size, weight or destination.

- Handling automated warehouses: In combination with warehouse management systems (WMS), KUKA robots enable a smooth flow of goods, eliminating the need for manual handling.

Automating these processes not only increases efficiency, but also minimizes the risk of human error and improves occupational safety.

3.2. Application in transport and distribution

In transport and distribution logistics, KUKA robots help optimize processes such as:

- Loading and unloading trucks: Thanks to their precision and ability to handle large and heavy loads, robots can automatically load and unload goods.

- Palletizing and unloading: Robots can quickly arrange products on pallets according to a specific pattern, which increases the efficiency of storage and shipping preparation processes.

- Inter-operational transport: KUKA mobile robots (AGV – Automated Guided Vehicles) enable autonomous movement of goods within a warehouse or production plant, which speeds up the flow of materials.

Thanks to their flexibility, KUKA robots can be easily integrated into existing logistics systems, allowing for a smooth transition to more advanced technologies.

4. Summary

KUKA robots are the undisputed leaders in automation and robotics, offering innovative solutions that are revolutionizing industry, logistics, medicine and many other sectors. Their versatility, precision and adaptability make them suitable for use in difficult workplaces. This applies to production lines, mechanical processing and logistics processes.

Continuous technological development and commitment to innovation make KUKA an indispensable partner in implementing the assumptions of Industry 4.0. If you want to maximize the potential of your company, choosing KUKA robots is an investment that will bring measurable benefits both today and in the future.