Table of Contents

Welding automation is becoming a key element of modern industry, bringing significant benefits in terms of efficiency, precision and work safety. OKIO MIG welding robots, thanks to advanced technology, enable achieving the highest quality standards, reducing operating costs and increasing production efficiency.

The importance of automation in welding

Nowadays, automation plays a key role in industry, increasing efficiency, precision and work safety. One of the areas where automation introduces revolutionary changes is welding. Thanks to modern welding robots, such as MIG OKIO welding robots, companies can achieve higher quality standards, reduce operating costs and increase production efficiency.

Automation in welding allows you to eliminate human errors that can lead to defective welds. MIG welding robots, equipped with advanced control systems, are able to perform welds with the highest precision, which is especially important in industries requiring high quality and repeatability, such as automotive, aviation or heavy industry.

What is MIG welding?

MIG Welding Definition:

MIG (Metal Inert Gas) welding, also known as GMAW (Gas Metal Arc Welding), is one of the most popular welding processes used in industry. This process involves the use of an electric arc that is created between the fusible electrode wire and the welded material. The wire is fed automatically from the roll through the welding torch, and the entire process takes place in a shield of inert gases such as argon or gas mixtures.

Basics of MIG welding:

In MIG welding, the electrode wire is fed automatically by the welding torch. This fixture is manually guided by a welder or automated using welding robots. As the electrode wire approaches the base material, an electric arc is created which melts both the wire and the surface of the base material, creating a weld. This process is relatively quick and efficient, making it ideal for mass production.

MIG welding is appreciated for its versatility and efficiency. It can be used to weld various materials, including steel, aluminum and alloys. Thanks to the automation of wire feeding and arc stability, MIG welding allows you to achieve high-quality welds in a short time, which is crucial in mass production.

Advantages of MIG welding

MIG welding offers many benefits that make it the preferred technique in many industrial applications. Here are some of the main advantages:

● High welding speed: Thanks to automatic wire feeding, MIG welding is much faster than traditional methods, which increases production efficiency.

● Ease of Use: The MIG welding process is relatively simple to learn and use, making it ideal for both beginners and experienced welders.

● Versatility: MIG welding can be used on a wide range of materials and thicknesses, making it versatile solution for various industries.

The advantages of OKIO MIG welding robots include high precision, efficiency and the ability to weld various materials. These robots are an ideal solution for companies in the automotive, aviation and many other industries, where the quality and repeatability of welds are crucial. Thanks to automatic MIG welding, the production process becomes more effective and operating costs are significantly reduced. Welding robots in industry are becoming increasingly popular because they offer unrivaled benefits in terms of speed, precision and reliability.

OKIO MIG technology

MIG technology is an innovative approach to the automation of welding processes. OKIO MIG welding robots have been designed to maximize welding efficiency and quality. Equipped with cutting-edge features such as advanced weld tracking systems, intelligent control algorithms and an easy-to-use user interface, OKIO MIG robots represent a breakthrough in the field of welding.

The new OKIO MIG welding robots are a response to the growing demand for automation in welding. Thanks to them, companies can not only increase their productivity, but also improve the quality of their products, minimize the risk of errors and reduce production costs. OKIO's MIG technology is an ideal solution for enterprises striving to gain a competitive advantage on the market.

OKIO MIG Welding Robots

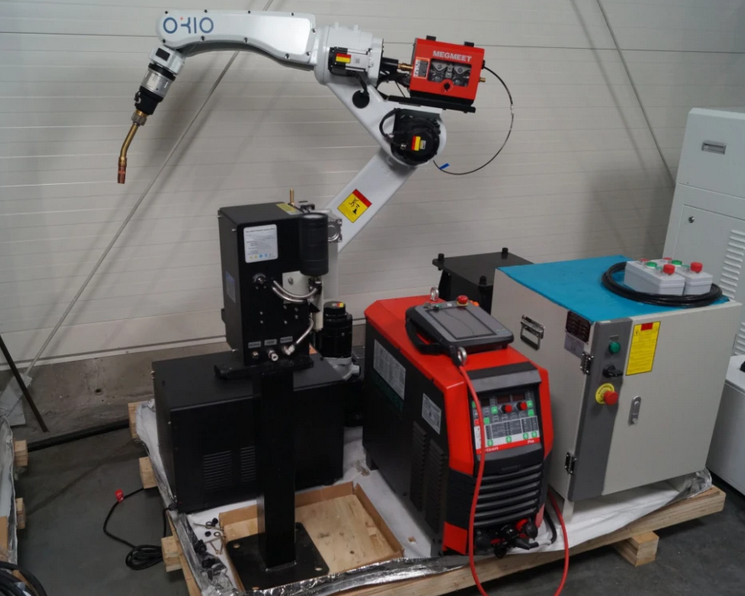

The new OKIO MIG welding robots introduce a revolution in the field of welding automation. Thanks to advanced functions and modern technology, these robots are able to perform precise and high-quality welds, which is crucial in the automotive, aviation and other sectors requiring reliable welding joints.

One of the leading products in our offer is the OKIO AB-1810PRO MIG welding robot

Specification:

- Range: 1800mm

- Load capacity: 6KG

- Robot weight: 200kg

- Power requirement: 3kVa

- Repeatability: +/- 0.08mm

- TRM welding torch

- Water cooling with anti-collision function

- Weld tracking function

- Integrated push welding torch drive - pull

- Supply voltage: 220v ±10%, 1 phase, 50 Hz}

- Source: Megmeet Artsen PRO 500PR (500A, Supply voltage: 380v ±10%, 3 phases, 50 Hz

Another robot that enjoys great customer recognition is the MIG OKIO AB-1510DEX

Specification:

- Range 1500mm

- Load capacity: 6KG

- Supply voltage: 220v ±10%, 1 phase, 50 Hz

- Source: AOTAI MAG-350RL (350A, Supply voltage: 380v ±10%, 3 phase, 50 Hz)

OKIO MIG robots are innovative welding robots that not only improve the quality of welds, but also increase production efficiency. Their advanced features, such as seam tracking and water cooling, ensure optimal welding conditions for better results.

End

OKIO MIG welding robots are revolutionizing the welding process, introducing unrivaled efficiency and precision to welding stations. With advanced technologies and features such as weld tracking and water cooling, these robots not only increase weld quality, but also reduce operational costs and minimize the risk of errors. In the era of Industry 4.0, investing in industrial robots such as MIG OKIO is a step towards more automated, efficient and competitive production.

MIG welding using robots allows you to achieve higher efficiency of welding robots, which translates into a significant improvement in the quality and repeatability of welds. Welding robots in production are reliable tools that meet the most demanding welding challenges, ensuring durable and high-quality connections. Thanks to OKIO MIG robots, enterprises can effectively increase their productivity and gain a competitive advantage on the market.