Table of Contents

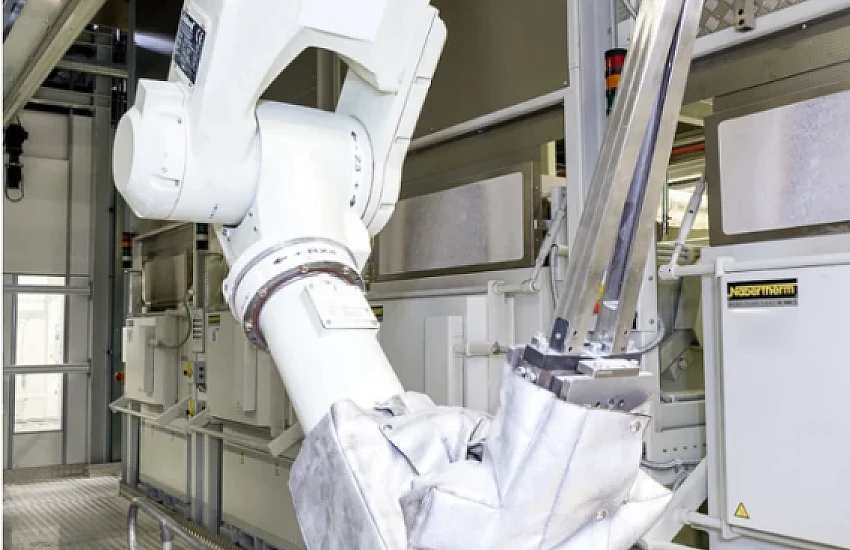

Production automation is becoming a key element for companies that strive to increase the efficiency and precision of their processes. Kawasaki stands out among the leading brands in the field of industrial robotics, offering reliable and technologically advanced solutions. One such product is the KAWASAKI FS060L E robot, equipped with a 12-meter roadway.

1. Introduction

Nowadays, automation of production processes is becoming an inseparable element of modern industrial plants. More and more companies decide to implement industrial robots, which significantly increase the efficiency, precision and productivity of production. Among the many brands offering advanced solutions in this area, Kawasaki stands out as one of the leaders in the field of robotics.

In this article, we will present the KAWASAKI FS060L E robot, manufactured in 2008, equipped with an impressive 12-meter roadway. This robot is designed to work in demanding production conditions, where both a large working range and a significant lifting capacity are crucial. The described solution can perfectly meet the needs of companies looking for a proven, efficient and solid automation system

2. Kawasaki - Leader in Industrial Robotics

Kawasaki's History and Achievements

Kawasaki Heavy Industries is a Japanese corporation with a long tradition, founded in 1896. Initially focused on the shipbuilding industry, it quickly expanded its operations to other sectors, including aerospace, automotive and rail. In the 1960s, Kawasaki also entered the industrial robotics industry, becoming a pioneer in this field.

Since presenting its first industrial robot in 1969, Kawasaki has been constantly improving its technologies. The company is responsible for introducing many innovations in robotics, making it one of the global leaders in this field. Their robots are used in various industries - from automotive to electronics and food production.

Kawasaki Robotics - Trusted Around the World

Kawasaki robots are used by thousands of companies around the world, which is evidence of the trust that users have in them. Thanks to their precision and solidity, these products can withstand years of intensive use, while offering low maintenance costs. Kawasaki is constantly improving its products, introducing technological innovations that respond to the dynamically changing needs of the industry.

3. KAWASAKI FS060L E Robot - Key Information

The KAWASAKI FS060L E robot is an advanced industrial device that is perfect for demanding production environments. It is a model designed for high precision, durability and efficiency, which means it can be used in a variety of applications, such as assembly, welding, material handling or packaging. In this part of the article, we will present the most important features and technical parameters of this robot to better understand its capabilities.

Year of manufacture: 2008

The KAWASAKI FS060L E robot was manufactured in 2008. Although it is an older model, its solid construction and advanced design still meet the requirements of modern production lines. Kawasaki, as a manufacturer known for the reliability of its products, ensures that its robots can operate without failure for many years, provided that they are regularly maintained.

- Maximum working range:

2,100 mm Thanks to its large reach, the robot is able to handle larger workspaces, which increases its flexibility in production applications. It also allows it to easily cover large distances between work points, which minimizes the need to reposition the robot or move production elements.

- Maximum payload: 60 kg

The 60 kg payload allows the KAWASAKI FS060L E robot to handle heavier components, which is invaluable in industries that require the handling of large elements, such as the automotive or metallurgical industries. The high load capacity increases the robot's versatility, making it suitable for tasks requiring both precision and force.

Applications and areas of use

The KAWASAKI FS060L E robot can be used in many industrial sectors, including:

- Production automation – thanks to its high precision and range, the robot is perfect for automated production lines where speed, repeatability and accuracy of operations are important.

- Automotive industry – its ability to manipulate heavy elements makes it ideal for assembly, handling of body parts or car components.

- Packaging and palletizing – the robot can effectively support the processes of packaging, palletizing and transporting goods, increasing the efficiency of production lines.

- Welding and material processing – thanks to appropriate configuration options, the FS060L E model can be equipped with welding tools, making it useful in the metal industry

4. Advantages of the KAWASAKI FS060L E robot with a 12-meter roadway

The KAWASAKI FS060L E robot, combined with a 12-meter roadway, is an excellent solution for companies that need maximum flexibility and reach in their production line. The roadway allows the robot to move along a defined path, significantly increasing its work area and efficiency.

The use of a 12-meter roadway allows the FS060L E robot to move freely along the production line, increasing its working range beyond the standard 2,100 mm. This means that the robot can service much larger areas without having to reposition other production elements. Such mobility gives companies greater flexibility in organizing the production space, which can lead to shorter production cycle times and minimal downtime.

In situations where operations must be performed over a large surface area, such as in material handling, component assembly or palletizing, the ability for the robot to move on the roadway allows it to perform tasks that would normally require multiple stationary robots. This not only increases efficiency, but also reduces the capital costs associated with purchasing additional equipment.

Conclusion

The KAWASAKI FS060L E robot with a 12-meter roadway is a unique solution that combines the robustness of the older model with an impressive range of operation. Thanks to its high payload, long reach and the mobility provided by the roadway, it is a versatile tool for automating various production processes. Although it was manufactured in 2008, it still offers excellent technical parameters that will meet today's industrial challenges. Investing in this robot model is not only a saving, but also a guarantee of reliability and increased production efficiency, making it an attractive choice for many industries.