Table of Contents

In an era of increasing automation, industrial robots are becoming an indispensable part of modern manufacturing plants. From simple, repetitive tasks to advanced operations requiring precision, robots significantly improve processes, increasing efficiency and reducing costs. In this article, we will look at the different types of industrial robots and their applications in key industries.

What are industrial robots?

Industrial robots are advanced mechanical devices designed to automate production processes. Their main purpose is to replace or support humans in performing repetitive, precise or dangerous tasks. These robots are most often controlled by computer programs, and their design allows them to perform many tasks with high precision and efficiency.

There are many types of industrial robots, from simple robotic arms to advanced systems that are able to move autonomously around the production floor. Thanks to them, industry can increase efficiency, reduce production costs and improve the quality of manufactured products.

The growing importance of robotization in industry

In recent decades, there has been a rapid development of robotization in various industries. The introduction of robots into production not only allows for an increase in the pace of work, but also for a reduction in errors resulting from human fallibility. Companies that decide to automate gain a competitive advantage by being able to produce faster and cheaper, while at the same time increasing the safety of their employees, who are less exposed to performing risky tasks.

Types of Industrial Robots

Industrial robots can come in many forms and functions, depending on the specific industry and tasks they are designed to perform. Here is an overview of the most commonly used types of industrial robots:

1. Collaborative robots (cobots)

Collaborative robots, also known as cobots, are robots designed to interact directly with humans in a production environment. Unlike traditional industrial robots, which often operate in closed safety zones, cobots can work alongside operators, supporting them in performing complex or tiring tasks.

Thanks to advanced sensors and safety technologies, cobots can detect the presence of humans and automatically adjust their movements so as not to pose a threat. Examples of cobot applications include assembly, packaging, palletizing, and quality inspection.

2. Industrial manipulator robots

Manipulator robots are the most commonly used type of robot in industry. They are usually robotic arms with several degrees of freedom that allow them to perform a variety of operations, such as moving, lifting, welding, painting, or assembling components.

3. Welding robots

Welding robots are robots designed to perform precise welding operations. Thanks to advanced technologies and control systems, they can perform both spot and linear welding with high accuracy, which allows for obtaining repeatable and high-quality welds.

4. Palletizing and packaging robots

Palletizing and packaging robots are designed to automate logistics processes, such as stacking products on pallets and packing them. Thanks to the use of advanced algorithms and image recognition technology, these robots can precisely stack products, optimizing space and protecting them from damage.

Application of industrial robots in various industries

Industrial robots have revolutionized many industries, contributing to increased efficiency, lower costs, and improved product quality. Each industry uses robots in a way that is tailored to its specific needs. Below are the key applications of robots in selected industries:

Automotive industry

The automotive industry is one of the earliest and largest users of industrial robots. Robots are used in various stages of car production, from welding, through painting, to assembly and quality inspection. By robotizing assembly processes, manufacturers can shorten the production time of one vehicle, thereby increasing their efficiency

Electronics industry

The electronics industry is characterized by high precision and miniaturization of components, which requires incredible accuracy in the assembly and inspection process. Robots in this industry are mainly involved in the assembly of electronic components, soldering microelements, as well as performing functional tests and quality control.

Logistics and warehousing industry

The logistics and warehousing industry uses robots primarily to automate processes related to the transport, storage and sorting of goods. AGV (Automated Guided Vehicles) and AMR (Autonomous Mobile Robots) robots are used to move pallets, boxes and other loads around warehouses and distribution centers.

Each industry uses robots in different ways, adapting them to its specific needs. This allows not only to increase production efficiency, but also to improve product quality and optimize costs and logistics processes. Robotization is becoming a key element of success in many industrial sectors.

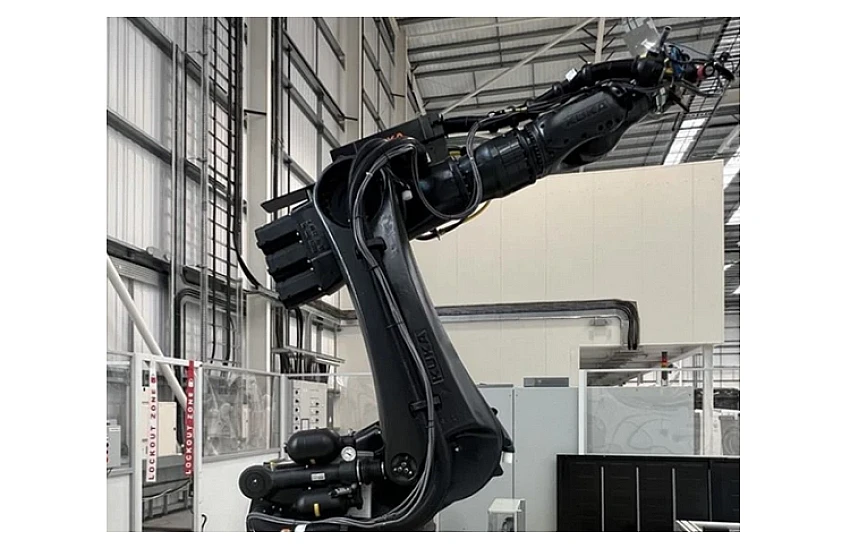

Offer for KUKA KR280 R3080 Fortec

An example of modern industrial automation is the KUKA KR280 R3080 Fortec robot. Manufactured in 2020, this model has 6 axes, a maximum reach of 3070 mm and an impressive payload of 280 kg, making it ideal for heavy tasks such as glue application in electric car production. Thanks to the modern KRC4 control panel and the fact that it has never been used, it offers reliability and unrivaled performance, contributing to increased efficiency and reduced operating costs in industrial companies.

- No. serial: 4380181

- Year of production: 2020

- Equipped with a glue application gun

- Axles: 6

- Max reach: 3070 mm

- Load capacity: 280 kg

- Control panel and KRC4 remote control

- Come from a plant for the production of electric cars

- No working hours - never worked

Summary

Industrial robots play a key role in modern production processes, supporting the development of many industries through automation and increasing efficiency. Thanks to the variety of available robot types - from cobots, through welding robots, to palletizing robots - companies can adapt solutions to their individual needs, improving product quality and optimizing costs.

Robots such as the KUKA KR280 R3080 Fortec are an excellent example of advanced technologies that allow for the implementation of complex tasks with high precision and reliability. Investing in modern industrial robots is a step towards more efficient, safe and competitive production, making robotization a key element of the future of industry.