Table of Contents

In an era of dynamic technological change and industrial transformation, collaborative robotics plays a key role in shaping modern automation. Universal Robots, as a pioneer in the field of collaborative robots (cobots), has created solutions that break traditional technological and financial barriers.

1. Introduction

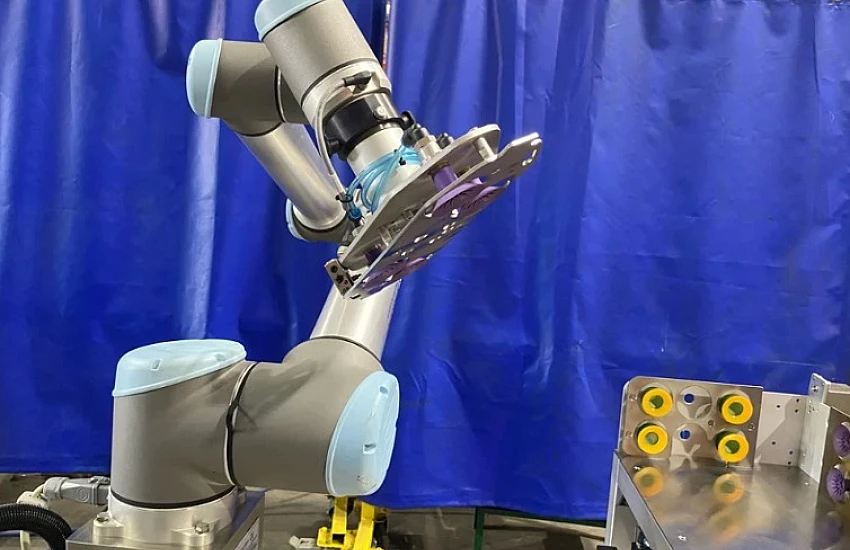

Universal Robots is a pioneer in the field of collaborative robotics (cobots). The company was founded in 2005 in Denmark by three engineers with the idea of creating collaborative robots that would be easy to integrate into production lines. Their goal was to break down the technical and financial barriers associated with robotics. Universal Robots cobots are characterized by flexibility, ease of use and safety.

2. What are collaborative robots (cobots)?

Collaborative robots (cobots) are modern industrial robots designed to work with humans in a shared workspace. Unlike traditional industrial robots, which often require separate zones secured by protective cages, cobots can work alongside operators without additional barriers, thanks to built-in safety systems.

Differences between cobots and traditional robots:

- Safety: Cobots have built-in sensors to detect collisions. Compliance with ISO standards.

- Easy to program: Intuitive interface allows for quick implementation without specialist knowledge. Programming by manual movement and graphical software.

- Mobility: Light, mobile and easy to move to different positions.

- Costs: Lower implementation cost, ideal for SMEs.

3. Main applications of Universal Robots

Cobots are used in many industries, from manufacturing to services. Here are the most popular areas of their use:

- Assembly and quality control: Thanks to their precision, cobots are perfect for the assembly of delicate components and in quality control processes, minimizing the risk of errors.

- Machine operation: Collaborative robots are ideal for feeding and receiving components from machines, which reduces the risk of accidents and ensures continuity of production.

- Palletizing and packaging: Cobots automate the processes of stacking, sorting and packaging goods, significantly accelerating production and logistics processes.

- Welding and other industrial processes: Robots have high accuracy. This makes them suitable for difficult tasks. Examples include precision welding, gluing and painting. This improves the quality and repeatability of work.

- Automotive: In the automotive industry, cobots support assembly processes, including assembling components, tightening screws and gluing. Additionally, they are used for quality control and machine operation, which increases the precision and reliability of the processes.

- Electronics: In the electronics sector, cobots are essential for precision tasks such as soldering, assembling small components and testing them, ensuring consistency and high quality of products.

A great example that has gained immense popularity in its category is the UR10 model. This is a device that perfectly combines high power with exceptional flexibility of operation, making it an extremely versatile solution.

Apart from the UR10 model, Universal Robots enjoy the greatest interest from Universities. Our cobots such as UR5 and UR3 have been purchased and are intensively used in the educational process, serving as an advanced training tool for future specialists. Thanks to this, students can gain practical experience in working with modern technologies, which prepares them for the challenges of the modern labor market.

4. Benefits of implementing Universal Robots

Universal Robots revolutionize the automation of production processes, introducing solutions available to companies of all sizes and types of activity. Unlike traditional industrial robots, UR cobots offer exceptional availability, efficiency and flexibility.

- Accessibility for small and mediumsized enterprises: Until now, production automation was the domain of large corporations due to high investment costs and complicated implementations. Universal Robots lower these barriers by offering cobots that are quick to install and inexpensive to maintain. Even smaller companies can afford to implement a robot, which increases their competitiveness.

- Increased production efficiency: Cobots eliminate monotonous and repetitive tasks that are time-consuming and prone to human error. By automating these processes, companies gain not only higher efficiency, but also better product quality. Employees can focus on more demanding and creative tasks.

- Operational flexibility: Universal Robots are designed to easily adapt to different production needs. They can be quickly reprogrammed for new tasks, making them ideal for dynamically changing business environments that require rapid response to market needs.

5. The future of automation with Universal Robots

The future of industry is inextricably linked to technological progress, and Universal Robots plays a key role in this evolution. With its innovative vision and collaborative robot (cobot) technology, the company is actively shaping Industry 4.0, where automation and digitization of production are becoming the standard.

Universal Robots cobots fit perfectly into this concept:

- Data collection and analysis: UR robots can collect information about their work and performance, which allows for real-time monitoring of processes and production optimization.

- IoT integration: By connecting to intelligent production systems, cobots can cooperate with other machines and automatically adapt to changing working conditions.

- Flexibility in production: Universal Robots cobots can be quickly adapted to new tasks. Thanks to this, companies can better respond to changing market needs. This also shortens order processing time.

Summary

Universal Robots is revolutionizing industrial automation with cobots – flexible, safe and easy-to-use collaborative robots. Cobots are used in many industries, from assembly to packaging, increasing efficiency, reducing costs and improving the quality of production. Models such as the UR10 support not only industry but also technological education. Universal Robots cobots enable companies to quickly adapt to changing market needs. This is an innovative solution that combines technology with efficiency, defining the future of automation.