Table of Contents

The WEISS rotator is a precision rotary table used in industrial automation, which increases the efficiency, reliability and accuracy of production lines. Check why it is an irreplaceable solution in a modern production plant.

1. Introduction

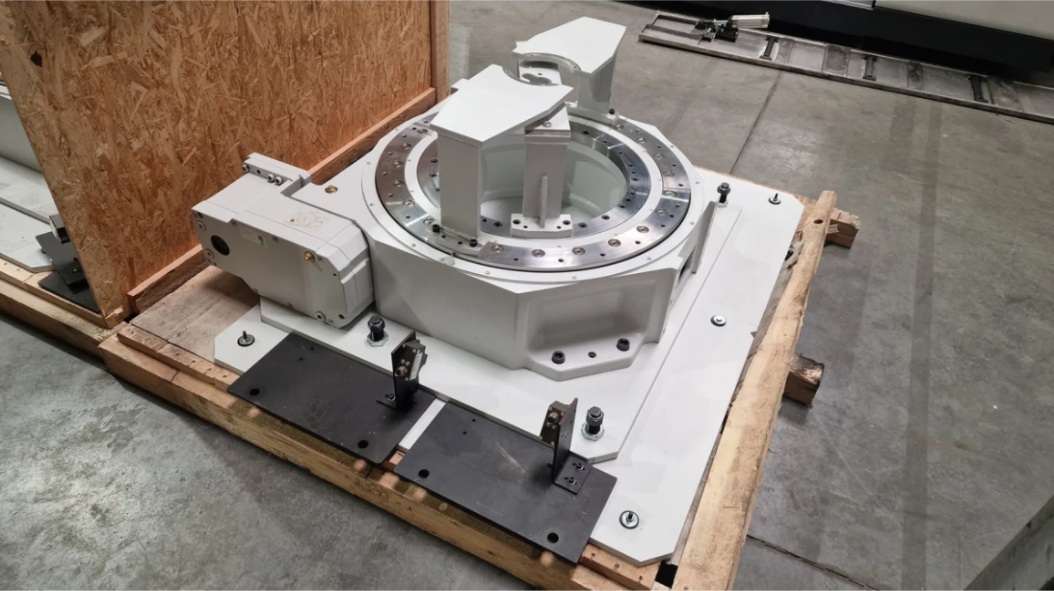

What is a WEISS rotator?

A WEISS rotator is a special mechanical device classified as a rotary table. It is used in industrial automation as part of advanced positioning systems. Its main task is to precisely position elements in a rotary motion, which allows for the automation of production lines.

Manufactured by the renowned German company WEISS GmbH, the rotator is a key component in assembly lines, assembly systems, indexing stations, CNC machines and automated production stations.

2. Key advantages and benefits

Choosing a WEISS rotator is a decision that translates into real time savings, improved precision and increased reliability of the production process. WEISS, as one of the leaders in the automation industry, provides solutions that are the result of many years of research, innovation and experience in cooperation with the largest manufacturers in the world.

Positioning precision

The WEISS rotator enables precise positioning with an accuracy of up to ±0.01 mm, which is crucial in industries requiring precise assembly, such as electronics, optics or medicine. Precise movement control eliminates errors and minimizes production waste.

Cycle speed and repeatability

Thanks to the optimized mechanical design and modern drives (e.g. servo and linear drive), WEISS rotators offer very short indexing times while maintaining cycle repeatability. This means higher line efficiency and a faster return on investment.

Durability and reliability

High-quality WEISS components, hardened surfaces and precise bearings ensure that the devices can operate continuously in 24/7 mode, maintaining constant operating parameters for many years. This minimizes downtime and maintenance costs.

Compact and modular design

WEISS rotators are available in many size and configuration variants as rotary modules. This design facilitates integration even in limited workspaces. The rotary module can be easily adapted to a specific application.

Easy integration with industrial automation

WEISS products offer compatibility with popular control systems (including Siemens, Allen-Bradley, Omron), and also support modern communication protocols such as Profinet, EtherCAT or Modbus. Integration with industrial automation and positioning systems is quick and easy.

Versatile applications

From simple applications to complex robotic systems - the WEISS rotary as an indexing table will prove useful in many industries. These include automotive, FMCG, pharmaceuticals, logistics, electronics production and others.

3. Technical specification of WEISS rotators

The WEISS rotator, available in our offer, is a device available in many design variants, thanks to which it can be easily adapted to the needs of various industrial applications. Regardless of the model, they have one thing in common - exceptionally high quality of workmanship and precise operating parameters.

Technical specification:

- Type: CR0900S-88

- Serial number: CR416156

- Year of manufacture: 2022

- Country of production: Niemcy

- Weight: 806 kg

- Gear ratio:312:1

- Speed: 9,6/min

- Torque: 13000 Nm

4. Industrial applications

The WEISS rotator is a component used in many industries where precision, repeatability and process automation are important. It is an important element of line automation and assembly system design.

Assembly line

In classic assembly lines, the WEISS rotator acts as an indexing table that precisely moves workpieces between subsequent workstations. This enables:

- smooth organization of work in cycles,

- integration with robots or vision systems,

- minimization of assembly errors.

Industrial robotics

Rotators are often used as rotating platforms for industrial robots, enabling dynamic change of the position of the workpiece. They provide:

- access to many sides of the workpiece without the need for repositioning,

- cooperation with cobots (collaborative robots),

- space saving thanks to compact design.

Transport systems and palletizing

In automatic internal transport systems, WEISS rotators enable precise rotation of pallets, boxes or workpieces, which allows for their:

- proper positioning for further processing,

- easy integration with belt or roller conveyors,

- better use of production space.

Automotive industry

In the automotive industry, rotators are used in:

- engine parts production,

- assembly of electronic components,

- testing and marking of components.

Pharmaceutical and medical industry

Thanks to their very high precision and the ability to work in cleanroom conditions, WEISS rotators are used in:

- dosing and packaging lines,

- testing and quality control systems,

- micro-assembly of medical components.

5. Summary

The WEISS rotator is a key element of modern industrial automation systems, combining precision, reliability and versatility of applications. Thanks to its solid construction, advanced technology and easy integration with various control systems, it is used in many industries - from automotive and electronics to pharmaceuticals and logistics.

Advantages such as positioning accuracy, fast cycle times, durability and compact design make WEISS rotators an ideal solution for companies focusing on automation and increasing production efficiency. The variety of models and a wide range of technical parameters allow you to match the device to the specific needs of each application.

By choosing a WEISS rotator, you are investing not only in a modern device, but above all in the reliability of processes, cost reduction and optimization of the entire production line.